Maximum Tungsten Carbide Frigus Heading Dies / Conglutinata Carbide Heading Dies

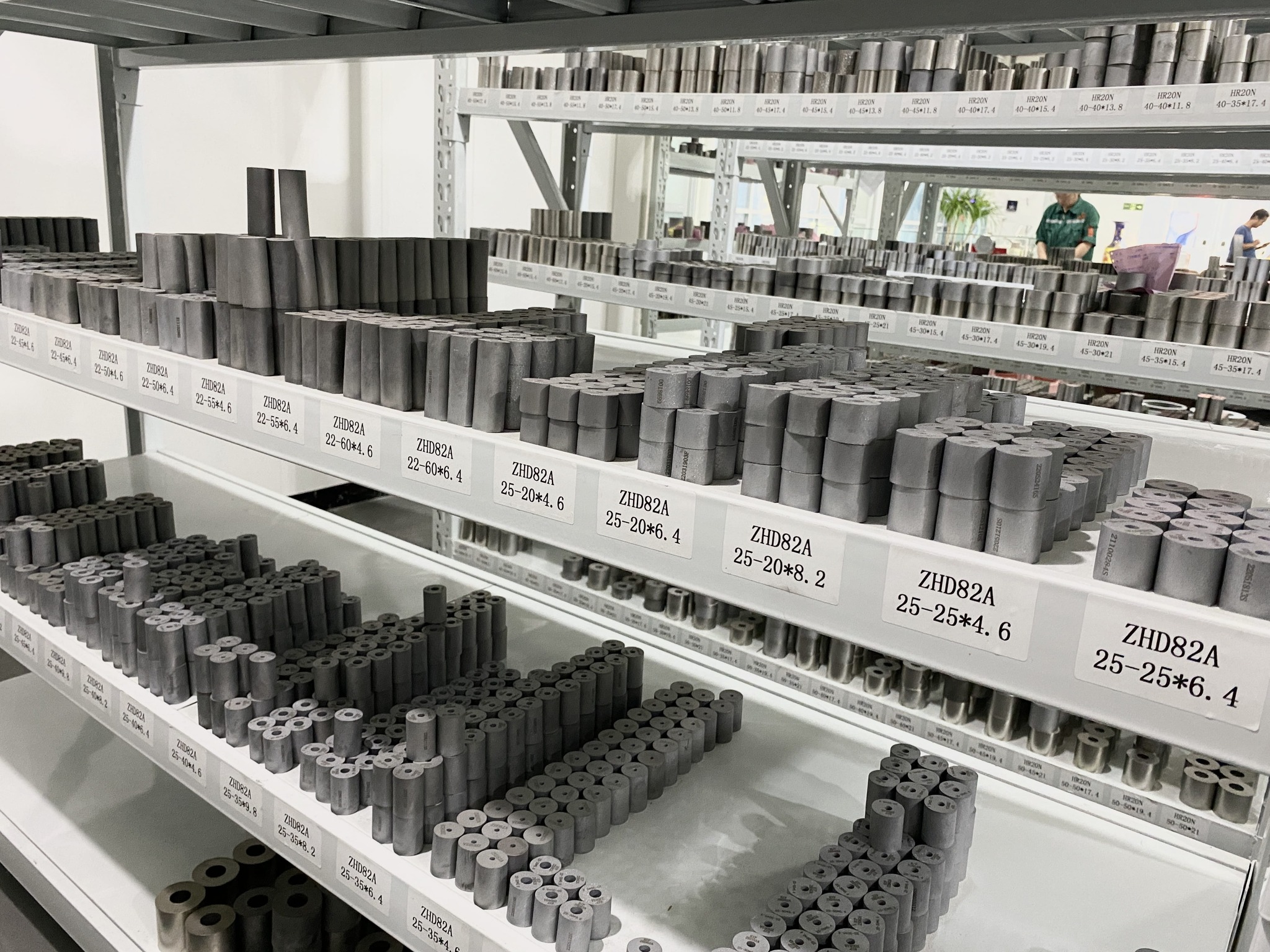

1. Factory Sinenses speciales in dispensando et productione, ISO certificatione.

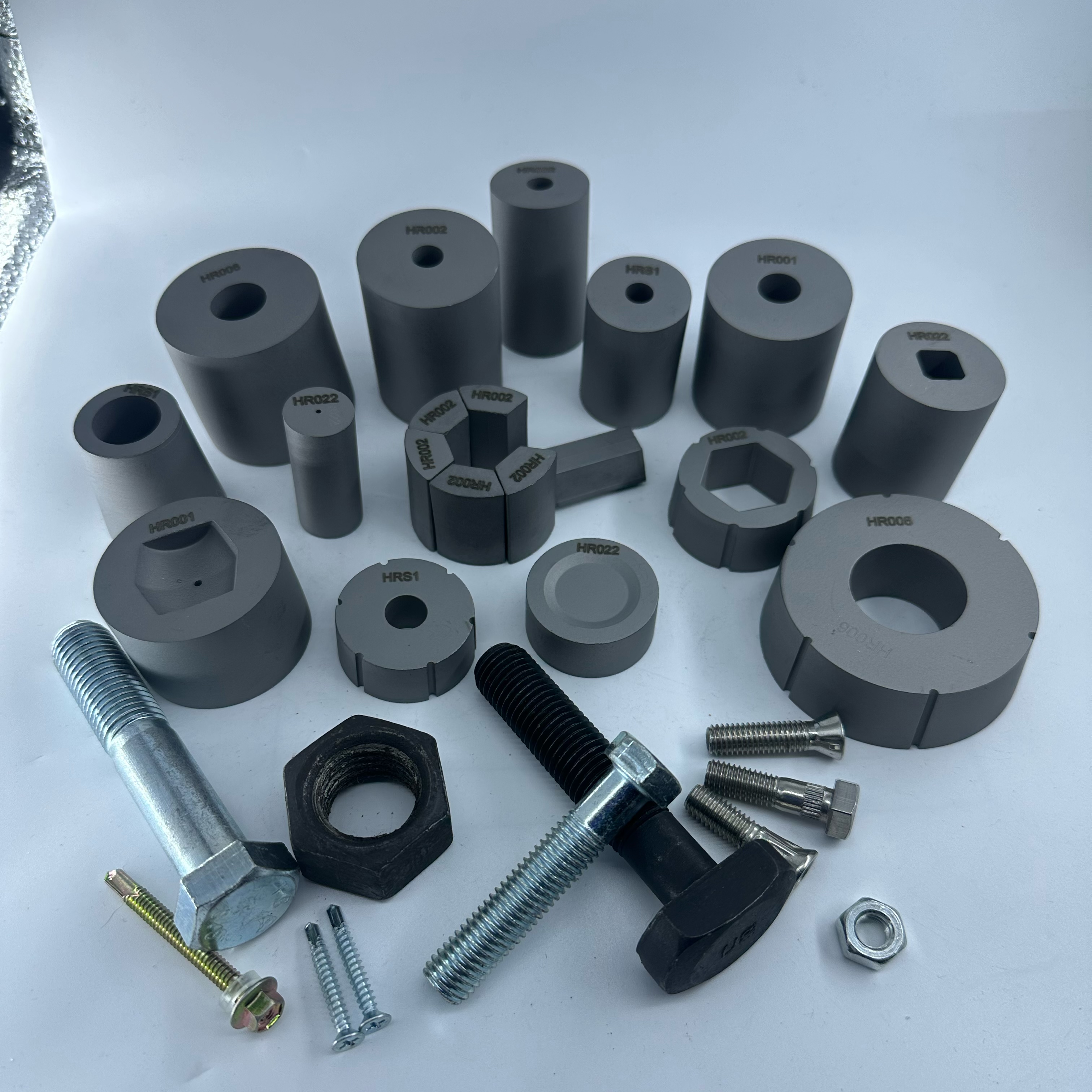

2. Magnitudines multiplices et rationes OEM praesto sunt.

3. E C% originale summus qualitas materiae

4. Lorem productio quadrigis, ieiunium partus

5. Free professional after-venditional service and technical support

| ungsten Carbide Frigus Forging / petere Dies | ||||

| Grades | Density | TRS | duritia | Euismod & application suadeo |

| g/cm³ | MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Formando vel terunt pro metallis pulveris et pulveris nonmetal. |

| YG15 | 14 | ≥3400 | 87.5 | Ad fabricandum trahens pora ferri fistulae et virgae sub Celsi compressibilitate rationis;pulsare, calcare, cudere instrumenta sub magnis vis. |

| YG20 | 13.5 | ≥3800 | 85.5 | Ad fabricandas stampas perit ad partes vigilias, laminas vernales instrumentorum musicorum, dolia altilium, globos chalybeos mediocres, cochleas, galeros cochleae. |

| YG15C | 14 | ≥4000 | 86.5 | nam oleum coni terebra calcaria mediae incisae molles et silices duri sunt;lignum congelatum, lignum molle, et lignum originale. |

| YG16C | 13.9 | ≥3500 | 85.5 | Im- pugnans, fictor, moritur. |

| YG18C | 13.7 | ≥3600 | 84.5 | Ictus resistendi cudendo perit, torcular cudendo moritur et scutulis. |

| YG20C | 13.5 | ≥3800 | 83.5 | Moritur indumentis repugnantis vel applicationis renitens impulsum. |

| YG22C | 13.3 | ≥4000 | 83 | Nux formans perit et in altum sol- sistentia cudendo moritur. |

| YG25C | 13.1 | ≥4250 | 82.5 | Immaculata fulmen capitis perit et tribulis. |

Materiam eu → Udo Ball Milling → mixta WC ac Cobalt Power → Pressing → COXA Sintering fornacibus → QC Deprehensio → sarcina

- Omnis processus productionis specialem hominem habet ad probandum ut qualitas

- Habete professionales fabrum ut reprehendo quod qualis

- All products are under strict quality system management based on ISO9001:2008

1. videre intra XLVIII horas;

2. Bonum communicatio Latina;

3. Professional suggestion on product;

4. Bona educatio venditio personam exercet;

5. Peritus in tungsten carbide venditur;

6. Post venditionem servitutis.

Moles onerarias productas intra XXX dies post pignus solvemus, dum, Si postulationes soecificae sunt in partus tempore.Mutationem secundum clientium petitionem facere possumus, quo brevior tempus partus absolute praesto est.

Solet 30% T/T in antecessum, libra 70% contra B/L exemplum.Posset etiam secundum clientium petitionem mutare.

Partes in variis formis et magnitudinibus fabricamus ut petitionibus clientium nostrorum exacte respondeant, sive caudices sive schedae, cylindrici, gestus, apices vel dentes egent.