Processus cryogenicus diversi causae mutationes in proprietatibus rerumcoaluit carbideac mutationes proprietatum evolutionis microstructurae propinquae sunt.Ideo necesse est ut ulterius influxum curationis cryogenicae in microstructura carbide concreta resolvere.

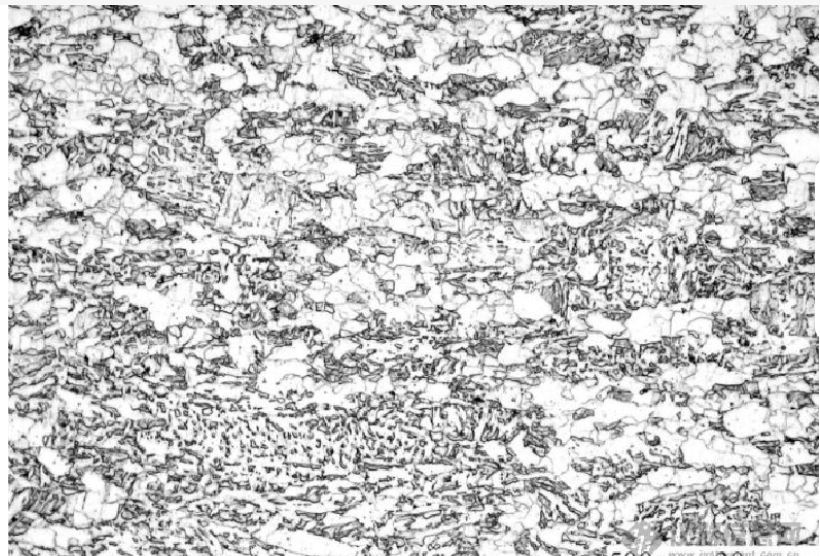

Microstructura typica WC-Co carbidi coagulo haec est: phase - WC (tempus durum);β pascha – Co (fasg ligans);y Phase - (TaC, TiC, NbC, WC) cancellos equicubicos carbides mixtas ;eta phase-decarburized phase (CoW, C, Co. W. C).Gill et al.schematicum schematicum in augmentis a et β dedit, ut in Figura 6. Ostensum est inter eos, α phase-WC (pars dura) principalem partem obtinet in.coaluit carbide materiain forma sceleti rigidi, cum β phase-Co (phasis ligans) arcte cum carbide (WC) cohaeret.

Cum carbide coagulo post sintering refrigeratur, cum magna moles W et C in Co dissolvuntur, summus temperatura phase α-Co in cella temperie adhuc stabiliter exsistit.Cum temperatura decrescere pergit, martensitica periodus transmutatio a facie centri cubico α-Co ad hexagonum ε-Co conferta occurrit in compage -Co.Perspici potest quod, mutatis temperaturis, mutationes in microstructurae sintcoaluit carbide, quae facultatem praebet curationi cryogenicae promovendi periodum transformationiscoaluit carbide.Multa studia de mutationibus in microstructura of posueruntcoaluit carbideante et post curationem cryogenicam et evolutionem microscopicam mechanismum exploraverunt cum proprietates macroscopicae mutant.

Post tempus: Mar-06-2024